During recent time period JETI has extended transmission system Duplex 2.4GHz offer by two new types of exchangeable transmitter modules, two types of interesting 5-channels receivers, expanders (allowing connecting through more telemetric sensors to one receiver) and MUI sensors (voltage & current telemetric sensors) for telemetrying, processing and calculating electric quantity. MUI sensors and its options made me write this article.

As you can see from the name, sensors are intended to measure voltage and current. They can be connected directly to Jetibox to create simple measuring equipment or they can be connected to every JETI Duplex receiver. Duplex then sends measured and processed data to the transmission module that generates acoustic notification and it also sends data to Jetibox where they are displayed and it also works as a programmer. A pleasant fact is that after the connection you needn’t adjust or activate anything. Functions and extended options of programming switch on automatically after connecting a sensor. If you disconnect the sensor, functions are not displayed in order not to complicate the programming. Term, known from the PC world, „plug and play“, could be paraphrased as „plug and fly“.

Nowadays you can buy 3 kinds of MUI sensors: MUI 30, 75, 150. Their functions are the same, they only differ in maximum current loading. Every sensor has two separated and detached inputs for measuring voltage and current. Thus you can measure voltage and current of one accumulator with just one sensor.

MUI sensors measure and compute these parameters:

| Functions | Values | Notification and other options | |

| Voltage |

- Minimal voltage - Maximal voltage - Actual data |

0-60 V | alarm U – acoustic notification if the voltage is under the set value |

| Current |

- Minimal current - Maximal current - Average current - Actual value |

up to 30, 75 , 150 A | alarm I – acoustic notification if current is over set value |

| Time | - measuring engine flight time | min:sec | adjustable value of activating current |

| Capacity | - monitoring the amount of energy taken from the accumulator | mAh | alarm C – acoustic notification if accumulator is depleted over the set value |

| Voltage measurement accuracy | 0,1 % | ||

| Current measurement accuracy | 1% | ||

It is worthless to go into details, you can download them easily from jetimodel.com. Once my friend’s MUI 75 was on my table to be assembled. I was thinking how it could be benefit for me. I prefer jet models to electric models. I got an idea to use it alternatively than it was produced for. I own turbine-engines models and their engines have got really high consumption - 1kg of kerosine is enough apx. for 3 minutes of flying thus you often fly till the last drop is in the tank. Jets often glide very badly during flying with engine switched-off. I got an idea to connect the sensor not as recommended (behind accumulator) but ahead of the appliance (in my case fuel pump) and use it as a fuel consumption gauge with acoustic warning when reached the minimum volume of fuel.

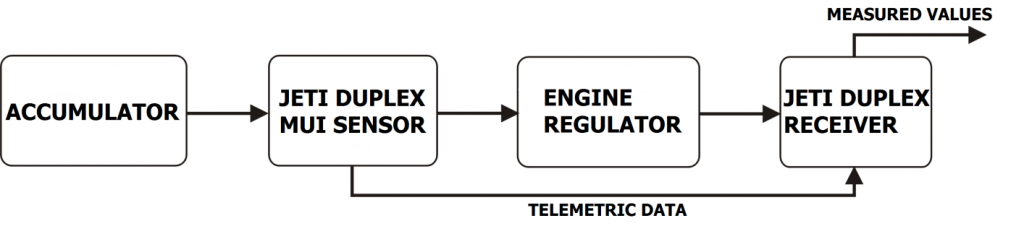

MUI sensor recommended connection

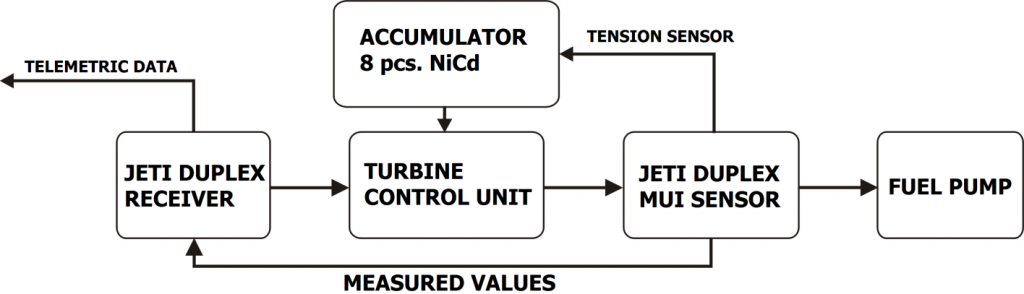

MUI sensor modified connection

If the dependance between the amount of energy consumed by pump and the amount of pumped fuel was linear, the MUI sensor would become elegant, small, and light fuel gauge that is able to process measured data, transfer them real-time to the transmitter but mainly give sound notification if the amount of fuel in tank is critical. Seems great theoretically but will it work?

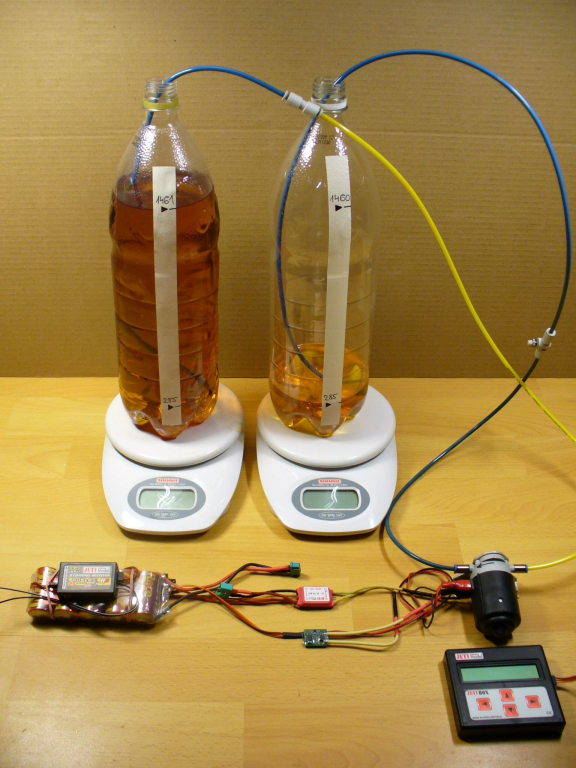

I have made a simple testing facility. I have adjusted DC regulator the range between 0,8 – 4,7V, this is apx. the range of controlling electronic of turbine. I have also choked outgoing tube in order its flow volume is the same as injection jets of turbine. I have used MUI 30 because maximal current taken by pump doesn’t reach 3A even during flying at full throttle. I have used fuel pumps for Frank, Graupner, Top Jet and two other manufacturers turbines. Fuel pumps for modeller turbines are simple gear-pumps powered by DC engines often of 300 or 400 series.

Then I started to pump, measure, write records….pump, measure…..

If my premise was right, the energy needed to pump equal amount of fuel should be the same for all kinds of fuel pumps. The fuel pump takes higher current during higher output, but it needs shorter time to pump equal amount of fuel. One of the fuel pumps increased its performance after every use. This fuel pump was absolutely new and hasn’t been used before. Measured values were senseless because of running-in, thus this fuel pump was taken out from the test. Other fuel pumps were used at least a part of season.

It is useless to put here a table with values, we can summarise the result into a few sentences:

- The dependence between between the amount of energy consumed by the pump and the amount of pumped fuel is linear.

- Rate of pumping has no influence on the result.

- The whole facility (control unit - current sensor - fuel pump) worked with maximal deviation of 4%.

- Conclusion – It works!

Maximal deviation might seem insignificant but if we have 3 litres of fuel in the plane, than 4% deviation stands for indispensable 120ml. This is not little, but I think this accuracy is enough for us. The difference was caused by fuel pumps. Deviation was almost non-measurable during running at half or full throttle. Highest deviations have appeared during free-running that is with voltage of 0,8 – 1,5V.

Practical use as well as the installation is very easy. We interrupt (cut) one line-wire (electric conductor) between the control unit and the fuel pump, and we put MUI sensor into the interruption. Mind the polarity! If you switch polarity, nothing will short out but the sensor won’t measure a current. We can use voltage measuring input to monitor turbine’s accumulator. This is how we can have monitored accumulator for receiver and servos (checked by sensor in receiver) and also accumulator necessary for running the turbine. Now it is necessary to find out how much energy is required for particular engine and model. We can let the turbine run out of fuel after landing and then take value „capacity“ from the memory of the sensor. Then we decrease this value by required fuel reserve and then we write this value to the memory of a sensor as „capacity alarm“ via Jetibox.

For example:

- Sensor has shown 200mAh as energy taken for depleting the fuel tank

- Required reserve is 20% of fuel in tank (=200 -20% = 160 mAh)

- We set „capacity alarm“ to 160

The result is that when the fuel pump after start up of the turbine consumes 160 mAh (takes 80% of fuel from tanks) , acoustic alarm gives me the notification. This works only when you start with full tank.

M. Pastyřík

Testing facility